CNC MACHINING PARTS

Aluminium Cast Tooling Plate Machining

- Skype: chalcoaluminum

- Phone: 86 17344894490

- Tel: 86 17344894490

- Email: business@chalcoaluminum.com

Chalco 5083 aluminum cast tooling plate has finer and homogeneous grain structure, with special state of stress digestion. Which makes almost no deformation after high speed of machining and cutting. Aluminum rolled plate sheet has orientated structure with strip distribution of grain along the processing direction, which makes more or less deformation of the parts after machining.

Cast aluminium tooling plate is manufactured close to finish thickness by a horizontal continuous aluminium flow casting process delivering a uniform fine grain structure.

The cast plate is then heat treated above 370°C for close to 10 hours to fully anneal (stress relieve) to remove any manufacturing stresses. The cast plate is then lightly machined to its finished size and protective films applied.

Specification of Aluminium Cast Tooling Plate CNC parts:

Alloy Compsition:

Alloy: EN573-3/3.3547 5083

Material features: Casting, homogeneity

Material Properties:

Machinability: very good

Weldability: Very good

Anodic oxidation properties: Good, not decorative

Polishability: Very good

Corrosion resistance: Very good

WEDN machining: good

Typical Mechnical Properties:

Tensile strength Rm: 240—290 Mpa

0.2% Yield strength Rp0.2: 110—130 Mpa

Breaking elongation A5%: 12

Brinell hardness HBW: 70

Typical Physical Properties:

Density: 2.66g/cm3

Thermal conductivity: 110—140W/(Mk)

Electrical conductivity: 16—19MS/m(m/Ωmm2)

Elastic modulus: ˜70,000N/mm2

Coefficient of thermal expansion: 24.2* 10—6/K

Thickness ranges and sizes:

Plate thickness between 5mm---100mm

Standard sizes are:

Thickness × Max. Width × Max. Length

>=5mm × 1520mm × 3020mm

>=10mm × 1570mm × 3670mm

>=15mm × 1860mm × 4000mm

Other dimension available on request

Main Attributes of aluminium Cast Tooling Plate CNC parts:

- Uniform fine grain structure

- Very low porosity

- Good tensile strength

- Good ductility

- Stress free condition similar to condition “0” temper wrought plate

- Ra 0.4 - 0.8 ųm finish to main faces, typically protected with thin polycoat film

- Very good flatness, typically 0.15 - 0.5 mm dependant on area of plate

- Very good machinability

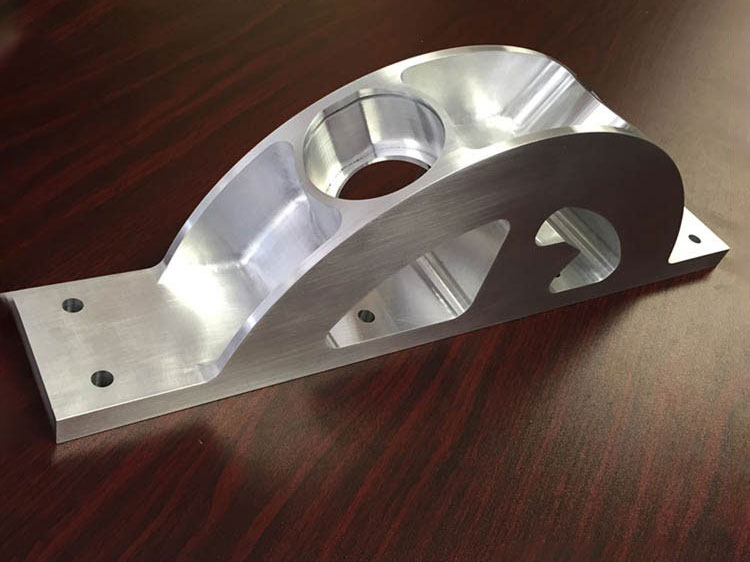

- Excellent dimensional stability even when heavily machined

- Excellent base material to start machining manufacture

- Excellent mechanical and dimensional stability when repeatedly heated and cooled in its application of use

- Annealing after machining is not required

- Good polishing characteristics

- Good anodising and hard anodising properties

- Excellent corrosion resistance

- Very good weldability

Typical uses of aluminium Cast Tooling Plate CNC parts: ship, automobile, aviation, Metro light rail, computer digital control (CNC) circuit board, chip printing device, circuit printing device, various instruments, screen display, dielectric, electronic equipment, food machinery, plastic injection mold, high strength and low residual stress components, indicator board, medical equipment, packaging machinery and model, pharmaceutical machinery, printing machine Robot technology, vacuum suction cup, decorative materials, testing equipment, vacuum equipment, etc. large area drilling, milling groove workpieces, non milling surfaces, workpieces with high requirements for flatness, and precision processing of equipment platform panel, bottom plate, vacuum equipment industry, glass touch screen equipment industry, etc.

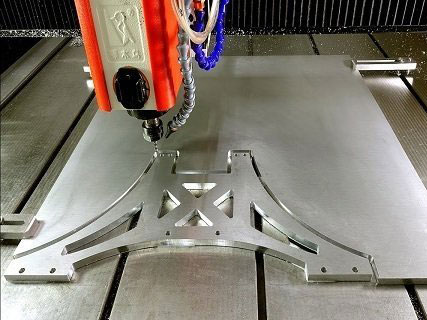

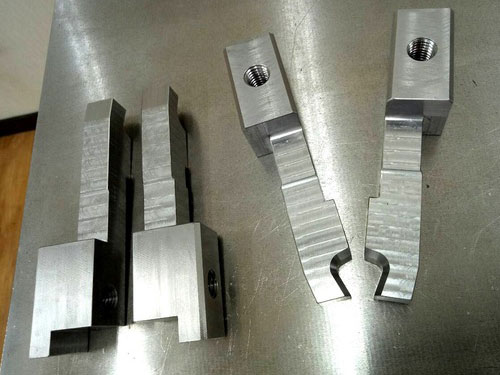

CNC MACHINING SERVICE

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts