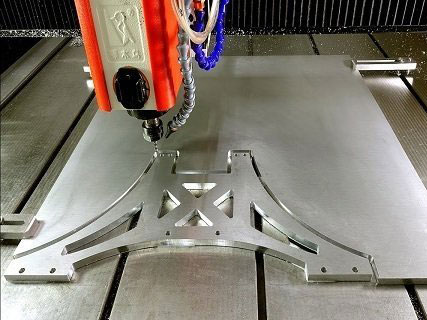

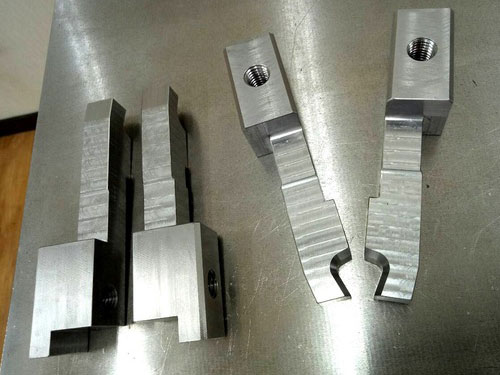

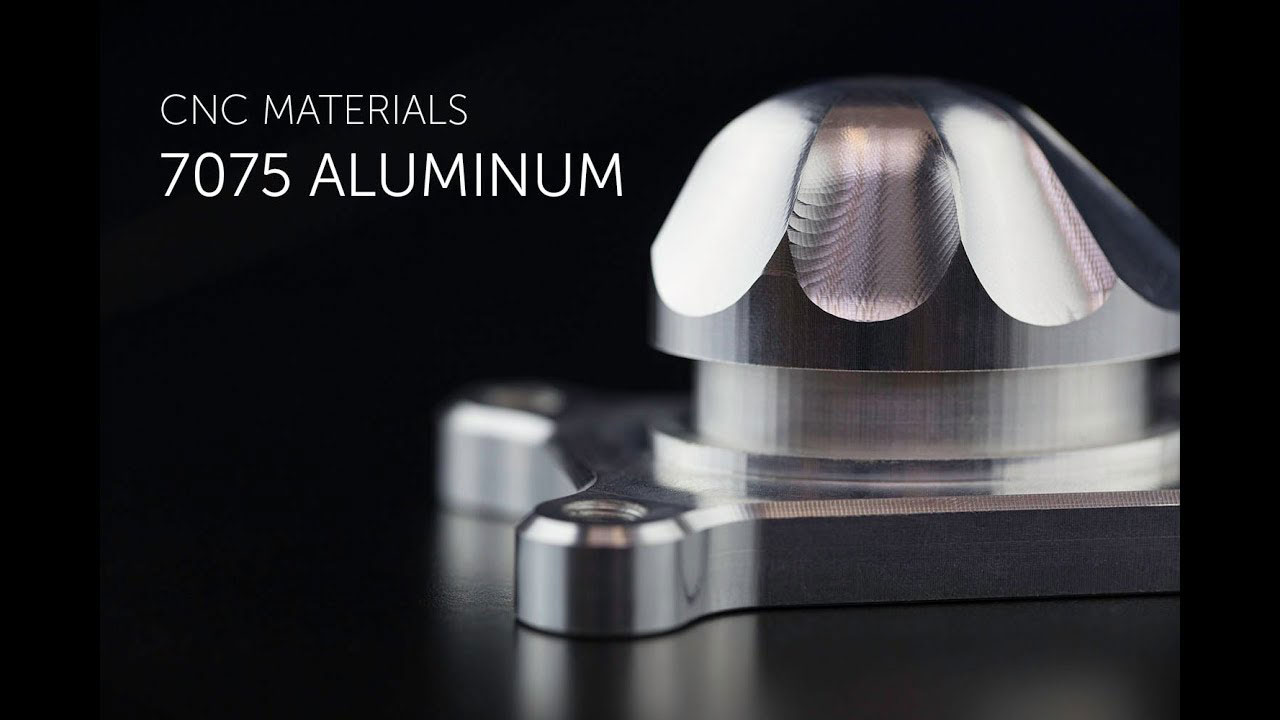

CNC MACHINING PARTS

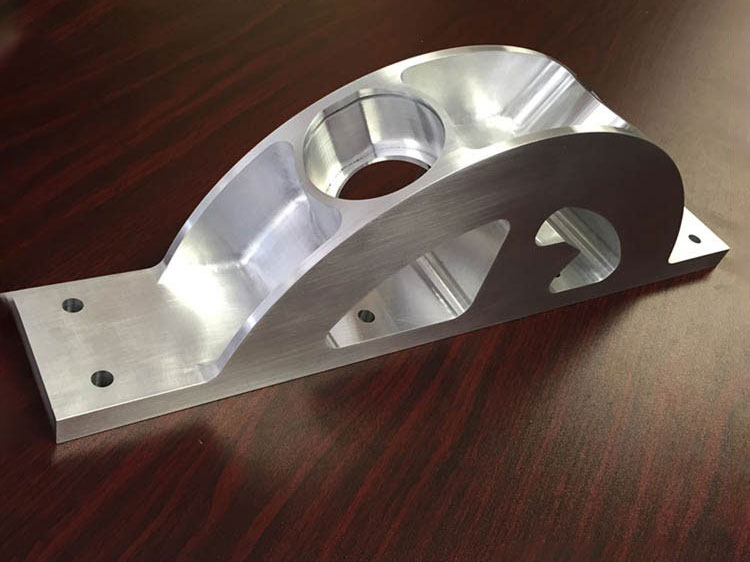

7075 aluminum CNC parts

- Skype: chalcoaluminum

- Phone: 86 17344894490

- Tel: 86 17344894490

- Email: business@chalcoaluminum.com

7075 aluminum CNC parts have good fatigue strength and average machinability, but is not weldable and has limited resistance to corrosion. Cost is higher compared to other aluminum alloys. Typically used in aircraft wings, fuselages, bicycle parts, and rock climbing equipment.

Main Attributes of 7075 aluminum CNC parts:

- Very high strength aluminium alloy (comparable to many steels)

- Good fatigue strength

- Increased strength at sub-zero temperatures

- Reduced strength at very high temperatures

- Less resistance to corrosion than many other aluminium alloys

- Some tempers offer improved stress-corrosion cracking resistance

- One of the highest strength to weight ratios of any aluminium alloy

- Generally speaking does not offer good weldability

- Heat treatable

- Can be highly polished

- Poor formability/workability

| Chemical Composition of 7075 alloy | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 7075 | 0.4 | 0.5 | 1.2~2.0 | 0.3 | 2.1~2.9 | 0.18~0.28 | ~ | 5.1~6.1 | 0.2 | ~ | 0.05 | 0.15 | Remainder |

| Alloy | Alloy Series | Main features | σb Value/MPa | Working Temperature/℃ |

| 7075 | 7075 series |

7075 T6 T62 T7351 aluminum alloy sheet plate is currently the most widely used 7 * * * aviation Aluminum Alloy, main supply varieties of aluminum or aluminum, heat treatment condition of O, T6, T73, T76. The static strength of T6 is the highest, the ductility is the lowest and the fatigue is the worst. It is sensitive to stress corrosion cracking, and toughness decreases with the decrease of temperature. So the T6 state is not applied to cryogenic working parts. T73 has the lowest state strength, but has high fracture toughness and excellent resistance to stress corrosion cracking and denudation. The performance of T76 is between T6 and T73. Compared with T6 state, it has low strength but good resistance to stress corrosion. Compared with T73 state, its strength is high, but its stress corrosion resistance is poor. |

421~538 |

<125 |

Main usage of 7075 aluminum CNC parts:

Aerospace industry, blow molding (bottle) mold, ultrasonic welding mold, golf head, shoe mold, paper mold, foam molding mold, dewaxing mold, template, fixture, mechanical equipment, mold processing, used to make high-end aluminum alloy bicycle frame.

CNC MACHINING SERVICE

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts