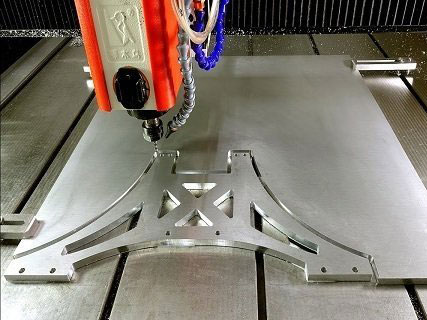

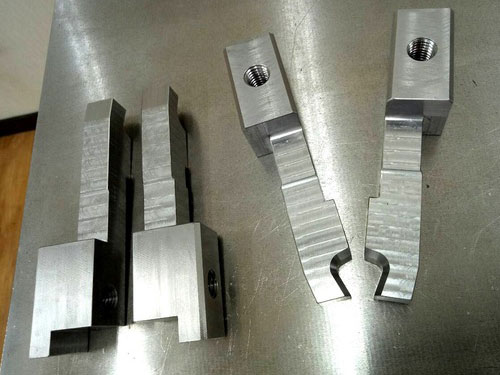

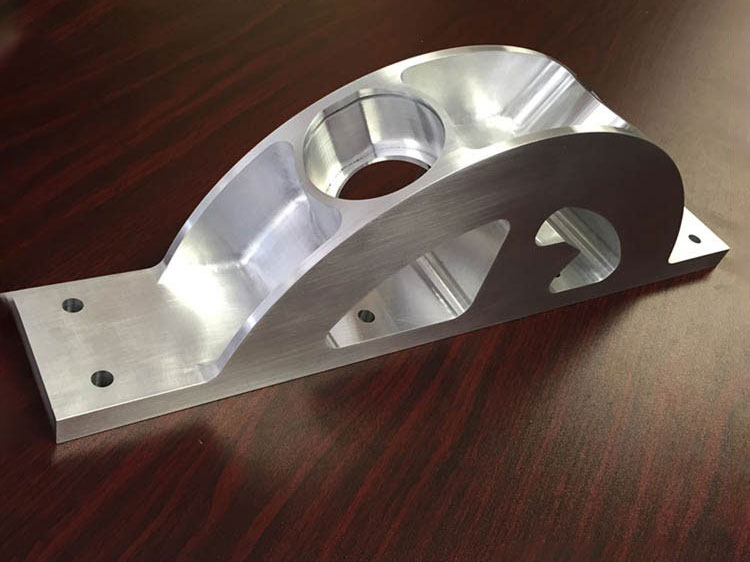

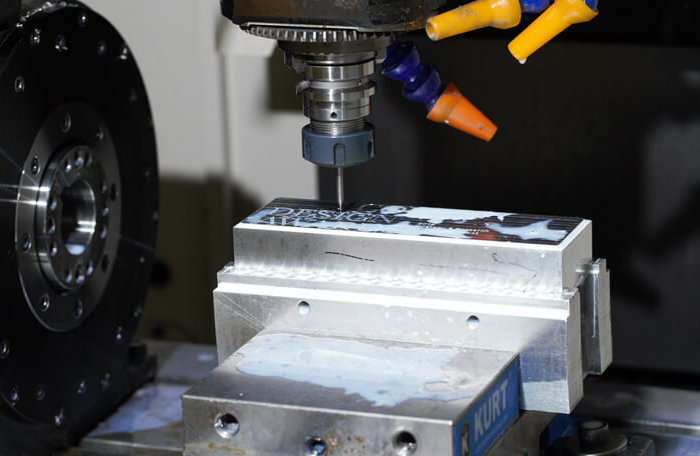

CNC MACHINING PARTS

2014 aluminum CNC parts

- Skype: chalcoaluminum

- Phone: 86 17344894490

- Tel: 86 17344894490

- Email: business@chalcoaluminum.com

2014 aluminum alloy has good machinability, good contact welding, spot welding and roll welding performance, poor arc welding and gas welding performance; it can be heat treated and strengthened, with extrusion effect.

Main Attributes of Aluminium 2014 aluminum CNC parts:

· Exceptionally high strength

· Very good machinability

· Heat treatable and retains good strength after heat treatment

· After heat treatment, behaves very much like low-carbon steel

· Poor resistance to atmospheric attack, especially in marine environments (therefore often hard anodised)

· Unsuitable for welding/brazing/soldering

· Great for parts needing good strength up to 150°C

| Chemical Composition of 2014 alloy | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 2014 | 0.50~1.2 | 0.70 | 3.9~5.0 | 0.4~1.2 | 0.2~0.8 | 0.10 | ~ | 0.25 | 0.15 | ~ | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Main features | Σb Value /MPa | Working Temperature /℃ |

| 2014 | Al-Cu-Mg | Heat treatment of reinforced alloys, the main varieties are rod and forgings. It has good thermal processing performance and is suitable for the manufacture of complex free forgings and die forgings. |

435~455 |

<175 |

2014 aluminum CNC parts can be used in applications requiring high strength and hardness (including high temperature). Aircraft heavy, forging, thick plate and extrusion materials, wheels and structural elements, first stage fuel tank and spacecraft parts of multistage rocket, truck frame and suspension system parts

Reasons to Choose Chalco:

· ISO 9001:2015 quality assurance· Consistent high quality machined parts

· Reliable delivery dates

· Exceptional customer service and communication

· Machining design advice

· Extensive experience in our field

PREVIOUS:No Previous NEXT:1100 aluminum CNC parts

CNC MACHINING SERVICE

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts