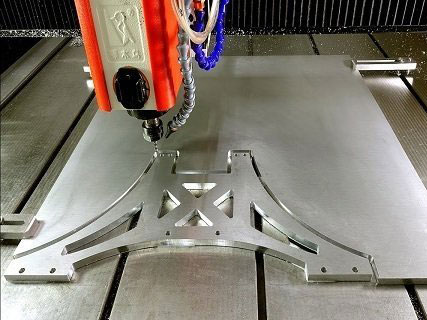

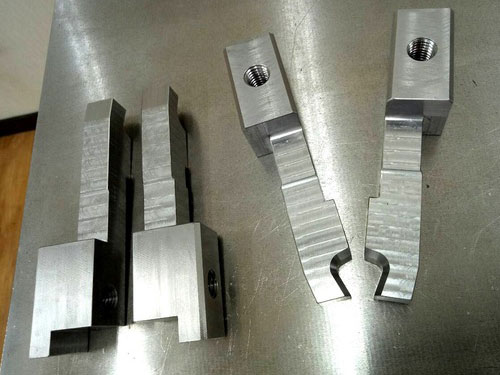

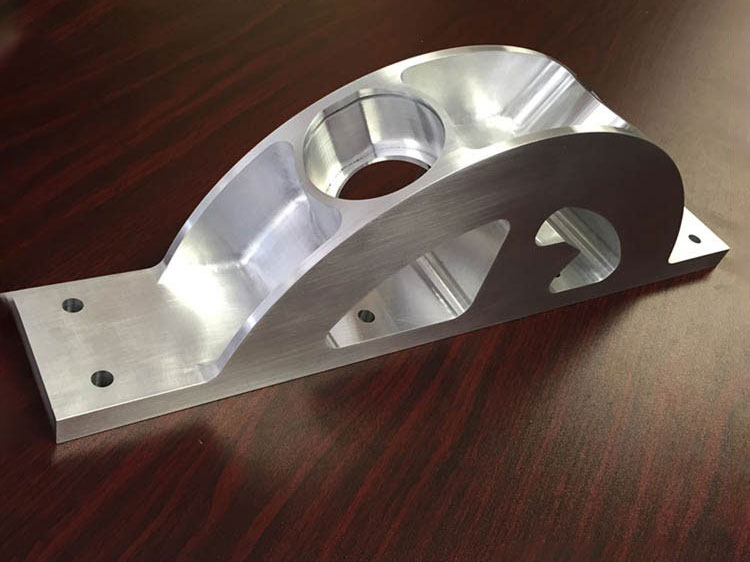

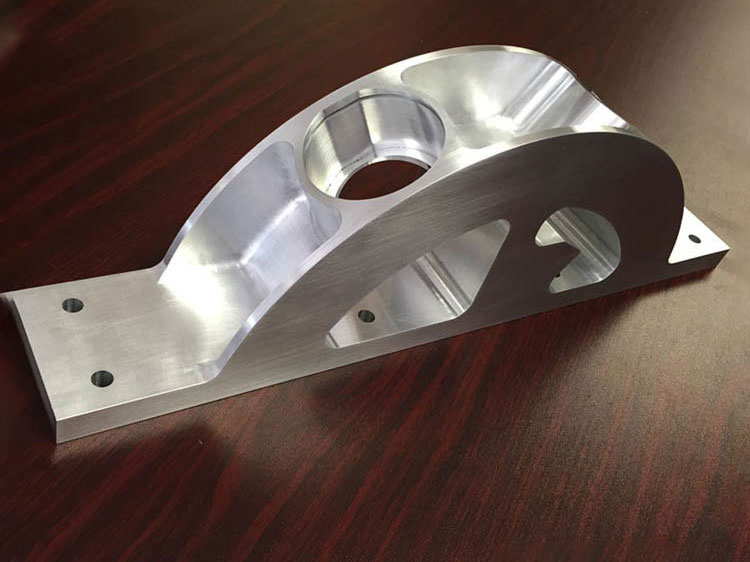

CNC MACHINING PARTS

2024 aluminum CNC parts

- Skype: chalcoaluminum

- Phone: 86 17344894490

- Tel: 86 17344894490

- Email: business@chalcoaluminum.com

2024 aluminum CNC parts have good fatigue resistance and average machinability, but is not weldable and has poor corrosion resistance. Used in application requiring a high strength to weight ratio such as aircraft wings, fuselages, and structures under tension.

Main Attributes of 2024 aluminum CNC parts:

- High strength

- Very good fatigue resistance

- Improved fracture toughness

- Fatigue crack growth

- Poor corrosion resistance to atmospheric attack

| Chemical composition of 2024 alloy | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Others | Al | |

| Each | Total | ||||||||||||

| 2024 | 0.50 | 0.50 | 3.8~4.9 | 0.3~0.9 | 1.2~1.8 | 0.10 | ~ | 0.25 | 0.15 | ~ | 0.05 | 0.15 | Remainder |

| Alloy | Alloy series | Main features | Σb Value/MPa | Working temperature /℃ |

| 2024 | Al-Cu-Mg | The heat-treated reinforced alloy is a common medium strength structural material, which can produce all kinds of semi-finished products. The commonly used T3 and T4, has high toughness and plasticity, good fatigue performance and anti crack performance, but poor corrosion resistance, less than 1mm thickness or molding, aluminum sheet and plate should be used, the short transverse properties and stress corrosion resistance are poor, not fusion welding and brazing. |

390~485 |

<150 |

2024 aluminum CNC parts is mainly used for making all kinds of high load parts and components (excluding stamping forgings), such as framework parts, skin, partition frame, wing rib, wing beam, rivet and other working parts below 150 ℃.

Reasons to Choose Chalco:

- ISO 9001:2015 quality assurance

- Consistent high quality machined parts

- Reliable delivery dates

- Exceptional customer service and communication

- Machining design advice

- Extensive experience in our field

PREVIOUS:1100 aluminum CNC parts NEXT:5052 aluminum CNC parts

CNC MACHINING SERVICE

- 3D Printed aluminum parts

- Aluminum parts anodizing

- Aluminum parts Brushing

- Aluminum parts buff polishing

- Aluminum parts CNC Turning

- Aluminum parts engraving

- Aluminum parts milling

- Aluminum parts powder coating

- Aluminum parts routing

- Aluminum plate sheet laser cutting

- Aluminum plate sheet turret punching

- Aluminum plate sheet water jet cutting

- Custom CNC aluminum parts